Can A Hydraulic Cylinder Be Used As A Pneumatic Cylinder?

Hydraulic vs. Pneumatic Cylinders

The source of confusion between hydraulic vs pneumatic cylinders has been going on for many years as their result and purpose seem to be extremely similar and some would argue, the exact same! So what does make these two applications so different? Can they be used interchangeably? How does each of them function that makes them different from the other? Let’s explore the differences and similarities of pneumatic and hydraulic cylinders so that we all have a better idea of what is best for each individual needs.

The two have many similarities! They both function in a very similar fashion, just with different means of movement. Both hydraulics and pneumatics require similar components, and the idea behind them both is that force is exerted, resulting in the ability to do something such as living, spinning, moving, or pushing. The possibilities are endless!

What Is the Difference?

The biggest difference between hydraulic vs pneumatic is actually the means by which the cylinder is working.

Pneumatics use gas, generally air or pure gas in order to transmit power by compressing the gas.

Hydraulics on the other hand use fluid, often oil, glycol, and other flame resistant liquid options.

Pneumatics in a very general sense are compressed air or gas that creates a linear force. They are pressurized systems that compress the air or gas in order to produce force allowing for movement to be created. The downside of pneumatic systems is that they really cannot produce more than 100 pounds per square inch (PSI) Because the pneumatic system is working with compressed air, there is a delay in movement, and also there is a requirement for a constant “compressor” source to keep things going. Some examples of pneumatic systems are a nail gun, pneumatic or “air” brakes used by busses and large trucks.

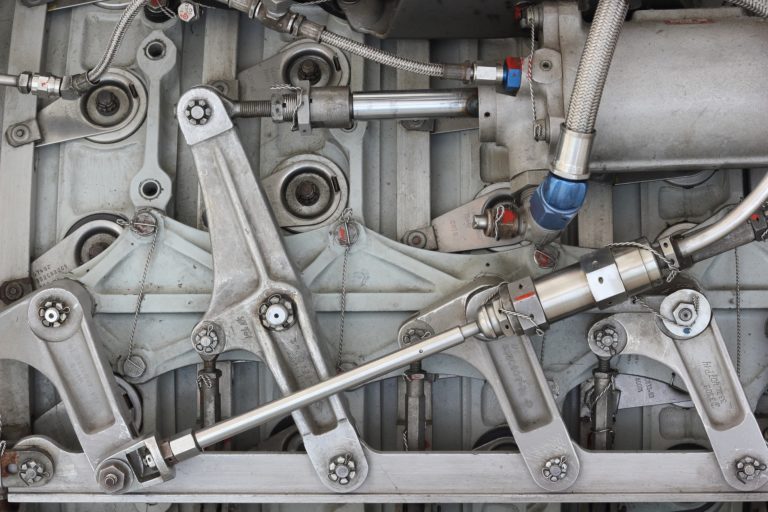

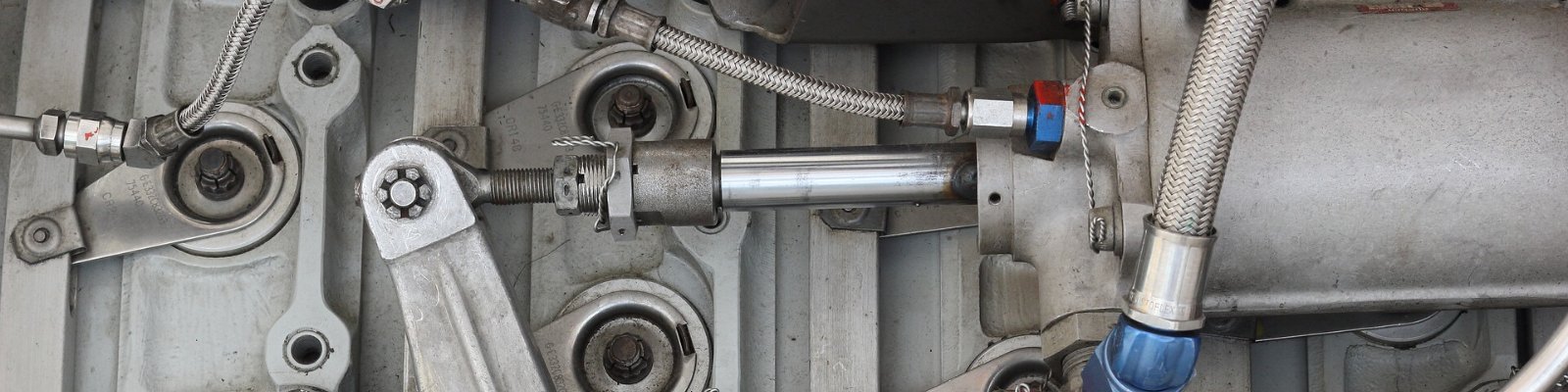

Hydraulics on the other hand is made up of a pressurized system rather than pressurizing gas or liquid. The pressurized hydraulic system uses moving liquids to move the pressure to different areas creating the force used to move the areas as needed. Hydraulic systems have the ability to create a much larger force, generally ranging from 1,500 up to 10,000 PSI which is obviously much more than what a pneumatic system can do. This results in a much larger ability to move and lift things – liquids are not very compressible which means that there is no delay in the movement. Some various examples of a hydraulic system in use are a dump truck, a hydraulic lift, and an excavator.

Pneumatic and Hydraulic cylinders are also made differently, generally, hydraulic cylinders are manufactured with thicker pieces of metal in order to be compatible with the high amounts of pressure moving within. With all of this information, we can know that although it might be POSSIBLE for a hydraulic cylinder to be used as a pneumatic cylinder, you ultimately want to keep them each in their retrospective areas for the best results.

If you have questions about your hydraulic or pneumatic cylinders or need to look into replacing your current cylinders, please see our pneumatic and hydraulic cylinders page and contact us today!