Hydraulic Fluid 101: Everything You Need to Know When Choosing a Fluid for Your System

Your pumps may become inefficient or even fail simply because you have used the wrong type of hydraulic fluid. How do you know if you are using the right kind of fluid for your specific hydraulic pump? The answer to that question is it’s dependent on several factors, including the type of pump you have, its maximum operating temperature, its maximum operating pressure, and the type of material that was used to make the pump’s seals.

Hydraulic Fluid

Hydraulic fluid 101: It can serve multiple purposes in a hydraulic system and its components including pumps. The purposes of hydraulic fluid include:

Lubricating Components within the Hydraulic System

Preventing Corrosion

Dissipating Heat

Transmitting Energy

Mainly, the most important factor of the hydraulic fluid is the ability of the fluid to transmit energy, but that can be compromised if too much heat is trapped within the pump, internal components are allowed to corrode, or there is not enough lubrication to prevent surface damage of the internal components.

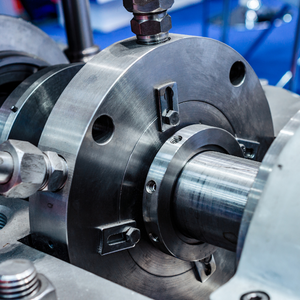

Why the Hydraulic Fluid is Important for Pumps

The hydraulic pump is known to be the heart of the hydraulic system, and if the wrong fluid is used it can impact the pump’s performance and life expectancy. This being said the use of a fluid that is poorly matched to the pump can lead to a failure that can cause cascading issues throughout the system. Issues that can arise if the wrong fluid is used include:

Excessive Heat Generation

Formation of Sludge and Varnish

Erosion and Excessive Surface Wear

Reduced Component Life

Significantly Reduces System Efficiency

If you notice any of these systems, it may be time to research a better-suited hydraulic fluid for your system.

Key Properties of Hydraulic Fluids

It’s important to understand what properties are important for your particular application before selecting a fluid for your system. The most important characteristics of hydraulic fluids include their viscosity, lubrication, thermal properties, flammability, stability, and foaming.

Viscosity

Viscosity is a measure of the fluid’s resistance to flow, with honey being an example of high viscosity, water being an example of medium-level viscosity, and most gases exhibiting very low viscosity. It is closely related to temperature, with hydraulic fluids becoming more viscous as temperature, with hydraulic fluids becoming more viscous as the temperature drops.

If a hydraulic fluid has a viscosity that is too high, the system will not run efficiently due to the losses involved in overcoming the resistance of the fluid to move. Additionally, damage can occur because components within the system will not be fully lubricated. However, if the viscosity is too low, there can still be some lubrication issues and the fluid might not be as effective at transmitting energy.

Lubrication

A good hydraulic fluid will serve as a lubricant throughout the system, protecting critical surfaces from damage and preventing metal-to-metal contact. In some instances, a hydraulic system or pump might require a hydraulic fluid with some additives to help maintain its lubricity in the presence of high pressures.

Thermal Properties

It’s important to keep in mind the system’s range of operating temperatures so the hydraulic fluid will remain stable and be able to maintain the desired viscosity. This can be a huge issue for equipment that is exposed to outdoor temperatures, especially when the temperatures drop below freezing. In addition, the fluids need to be able to dissipate the heat that is generated by pressure drops and friction.

Flammability

Hydraulic fluid should have a high flashpoint when being used in an explosive or highly flammable environment. The flashpoint is the temperature at which the hydraulic fluid gives off enough vapor to ignite in the air. However, keep in mind that hydraulic fluids can easily ignite if they are discharged under high enough pressure to produce a fine oil mist. Hydraulic fluids should have a non-petroleum makeup or contain a large amount of water If flammability is an issue.

Stability

If possible, the hydraulic fluid should be non-volatile. It should remain both physically and chemically stable in the presence of extreme pressure fluctuations, a wide operating temperature range, and even long-term storage.

Foaming

Another potential issue to look out for with hydraulic fluids is foaming, which occurs when the hydraulic fluid releases trapped gases. Foaming is a result of increased system temperatures as well as a loss of hydraulic fluid as the gases are released.

Types of Hydraulic Fluid

There are three types of basic hydraulic fluid: water-based, petroleum-based, and synthetic. Each type has its own characteristics that make it ideal for certain systems. In addition, there are some fluids that are ideal for applications that can affect the environment.

Water-Based Hydraulic Fluid

This is the oldest type of hydraulic fluid but in modern times is not used as much as the other types. Keep in mind that while water may not be as effective at lubrication, it’s ideal for situations where the possibility of fire is a concern. Water-based fluids tend to be cheaper than synthetic fluids but still more expensive than petroleum-based fluids.

Petroleum-Based Hydraulic Fluid

This type of hydraulic fluid is far more commonly used than water-based fluids and is a cheaper alternative to synthetic fluids. Various types of petroleum-based fluids are different from each other based on how the petroleum products are processed:

Group I: Produced from Solvent Neutral Mineral Oils

Group II: Comprised of Hydroprocessed Base Oil

Group III: Comprised of Hydrocracked Base Oils

Additives comprise about 1% or less of petroleum-based fluids but have a tremendous impact on hydraulic fluid performance. Key additive package components include antioxidants, anti-wear components, foam inhibitors, viscosity modifiers, and rust inhibitors.

Synthetic

This type of hydraulic fluid is man-made and designed specifically to provide high-performance properties that work well in flammable environments. Synthetic hydraulic fluids are the most expensive but work better than other types of fluids when exposed to extreme temperature variations and high pressures. However. Unlike petroleum-based and water-based fluids, they may be incompatible with certain seal materials and can be toxic.

Let's Wrap It Up on Hydraulic Fluid 101:

Unless your system is being used in a very flammable environment, either petroleum-based or synthetic fluids should work well. The viscosity of fluid- which is one of the most important factors involved when selecting a hydraulic fluid- is heavily dependent on both temperature and pressure, with low-temperature working conditions requiring a lower-viscosity fluid. Additionally, the fluid needs to be chemically compatible with the seals used in the pump; this is typically a problem related to the use of synthetic fluids.

All Phase Hydraulics offers maintenance plans to help meet your preventative maintenance needs and goals- and this includes making sure that the most appropriate hydraulic fluid is being used in your system.

Contact Us Today to Find Out How We Can Help Your Hydraulic Systems Achieve Peak Performance.