The Ultimate Guide to Hydraulic Hose Repair Service and Maintenance

Welcome to our comprehensive guide on hydraulic hose repair and service!

If you work with hydraulic systems, you’re probably well aware of the critical role these hoses play in keeping things running smoothly. From the various types of hydraulic hoses and their materials to the intricate world of fittings, connectors, and essential components, this blog will be your go-to resource for understanding, maintaining, and repairing hydraulic hoses.

We’re here to demystify the complexities, provide practical advice, and help you ensure that your hydraulic systems stay in tip-top shape. So, let’s dive right in and explore the inner workings of hydraulic hose repair service.

Looking for Hydraulic Hose Repair Service near Grand Rapids Michigan?

Table of Contents

Parts of a Hydraulic Hose

The hydraulic hose is a vital component of any hydraulic system, and understanding its anatomy is crucial for proper maintenance and repair. It consists of several key parts:

Inner Tube

This is the innermost layer of the hose and is in direct contact with the fluid being conveyed. It’s typically made of synthetic rubber or other materials compatible with the type of fluid being used.

Reinforcement Layer

Surrounding the inner tube is the reinforcement layer, which provides structural support and helps the hose withstand high pressure. This layer is usually made of high-strength materials like steel or synthetic fibers.

Outer Cover

The outer cover serves as a protective layer for the hose, shielding it from environmental factors, abrasion, and other potential damage. It’s crafted from materials designed to resist wear, weathering, and chemicals.

Braid or Spiral

Some hydraulic hoses feature an additional layer of reinforcement in the form of a braid or spiral. This provides extra strength and flexibility, allowing the hose to handle higher pressure levels and more demanding applications.

Fitting Ends

The ends of the hydraulic hose are fitted with connectors, typically made of metal, that allow the hose to be attached to other components of the hydraulic system.

Types of Hydraulic Hoses

A hydraulic hose, in its essence, is made from a variety of materials designed to withstand immense pressures and harsh environments. These hoses are often crafted from a blend of synthetic rubber, thermoplastics, or even metals like steel for reinforcement. All Phase Hydraulics uses Parker brand hoses and fittings to ensure that your machines are only running with the best of the best.

Synthetic Rubber Hydraulic Hoses

Synthetic rubber hoses exhibit commendable flexibility and resistance to wear and tear, making them a popular choice in diverse applications. Synthetic rubber hydraulic hoses are highly regarded for their impressive flexibility and exceptional resistance to wear and tear. This quality makes them a favored option across a wide range of applications. Their robust construction allows them to withstand the demanding conditions often encountered in industries such as construction, agriculture, manufacturing, and automotive. Furthermore, synthetic rubber hoses are known for their ability to maintain their structural integrity even when exposed to harsh environmental factors, including extreme temperatures and chemicals. This reliability ensures that they can effectively serve as conduits for transmitting hydraulic power within various machinery and equipment, contributing significantly to their overall efficiency and longevity. With their adaptability and durability, synthetic rubber hydraulic hoses continue to play a vital role in numerous industrial sectors.

Thermoplastic Hydraulic Hoses

Thermoplastic hydraulic hoses are a critical component in various industries due to their unique properties. Their lightweight nature and impressive abrasion resistance set them apart, making them invaluable in applications demanding high pressure. These hoses excel in situations where maneuverability and ease of handling are crucial, thanks to their reduced weight compared to traditional alternatives. However, it’s important to note that they may not perform optimally in extreme temperature conditions. In situations where temperature fluctuations are extreme, alternative hose materials may be considered to ensure optimal performance and longevity. Nonetheless, in many applications, the benefits of thermoplastic hoses far outweigh their limitations, making them an essential choice for many industries.

Steel Hydraulic Hoses

Steel hydraulic hoses are renowned for their unmatched strength and rigidity, making them a formidable choice for applications that demand durability and reliability under extreme pressure. Crafted from robust steel materials, these hoses exhibit exceptional resistance to wear and tear, ensuring longevity even in the harshest environments. However, their inherent stiffness comes at the cost of flexibility. This rigidity may limit their application in situations where tight bends or intricate routing is required. Despite this, in scenarios where raw power and resilience are paramount, steel hydraulic hoses remain the go-to choice, offering a level of robustness that few other materials can match.

Common Causes of Hydraulic Hose Failure

Environmental Factors

One of the primary culprits behind hydraulic hose failures is environmental conditions. Exposure to extreme temperatures, chemicals, UV radiation, and abrasive substances can gradually weaken the hose material over time. It’s crucial to assess the operating environment and choose hoses with the appropriate materials and protective measures to ensure longevity.

Operational Errors

Incorrect usage and handling can lead to premature hose failure. This includes over-bending, kinking, twisting, or allowing the hose to rub against other surfaces. Additionally, exceeding the recommended pressure limits or subjecting the hose to sudden, excessive pressure spikes can result in catastrophic failure. Proper training and adherence to operational guidelines are essential in preventing these types of errors.

Material and Manufacturing Issues

Material and Manufacturing Issues: Even high-quality hoses can suffer from defects or weaknesses in material composition or manufacturing processes. These can manifest as weak points, irregularities, or internal flaws that may lead to eventual failure. Regular inspections and sourcing hoses from reputable manufacturers are crucial in minimizing the risk of such issues

Signs of Hydraulic Hose Wear and Tear

Just like with a worn-out pair of shoes, there comes a time when a hydraulic hose needs to retire. If you notice any of the common indicators mentioned earlier, it’s a definite red flag. Additionally, if a hose shows signs of ballooning or kinking, it’s a clear signal that it’s struggling to bear the pressure. Another critical factor is the age of the hose. Hoses have a finite lifespan and with time, they naturally degrade. Regular inspections are like health check-ups for hoses, ensuring they’re still fit for duty.

Key Indicators for Replacement

Leakage

Any visible oil or fluid leakage around the hose or fittings is a clear sign of damage.

Cracks

Small or large cracks on the surface of the hose material are a clear indication of wear.

Abrasion

Excessive friction or rubbing against other surfaces can cause outer cover abrasion.

Bulges or Blisters

Areas where the hose appears swollen or deformed can be a sign of internal pressure issues.

Mushy Texture

A hose that feels unusually soft or mushy to the touch may be compromised.

Frayed or Torn Cover

The outer layer of the hose should be intact. Fraying or tearing is a sign of wear.

Hardening/Brittle

Conversely, sections of the hose that feel stiff or rigid could indicate damage.

Corrosion of metal parts

This is especially relevant for metal components and can weaken the integrity of the hose.

Performance Issues

A decrease in hydraulic system efficiency or effectiveness may be attributed to hose wear.

Age and Usage

Over time, hoses naturally wear out. Regular inspection and replacement are essential preventive measures.

Cost Considerations

Deciding when to replace a hydraulic hose isn’t just about the wear and tear—it’s also about practicality. Sometimes, the cost of repairing a hose might outweigh the benefits, especially if it’s an older, extensively used one. Investing in a new hose can save on potential downtime and maintenance costs in the long run. It’s like making a smart financial decision that not only ensures safety but also keeps the machinery running smoothly. Balancing the initial expense of replacement with the potential savings in maintenance and operation can be the key to making a wise choice.

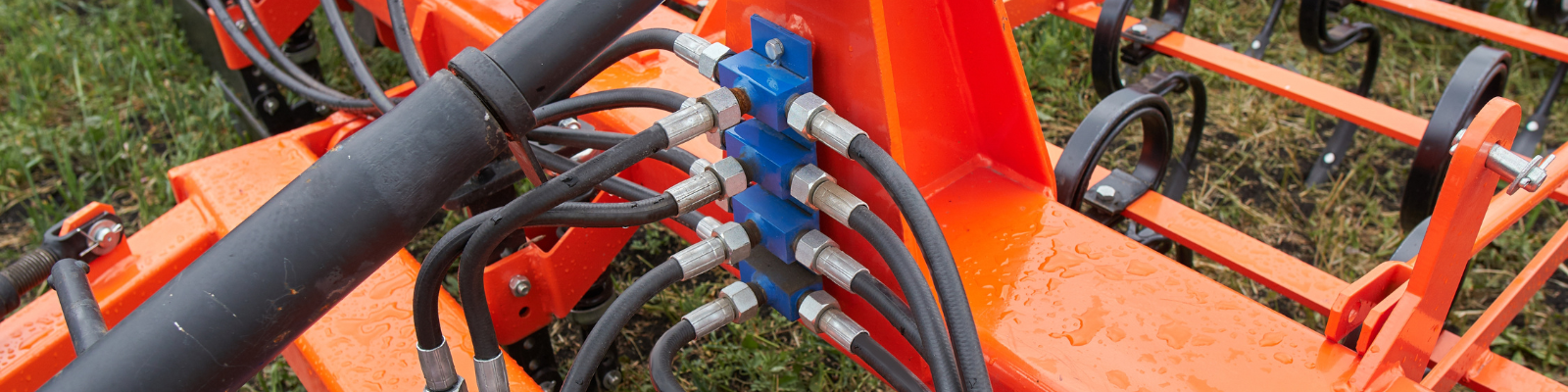

Hydraulic Fittings and Connections

Finding the Proper Fit

Choosing the right Fittings

Making the correct selection involves considering factors like thread size, connection type, and material compatibility. This ensures that the fitting can withstand the operating conditions and effectively link the system components.

Proper installation and tightening of fittings are crucial for a secure connection. This helps prevent leaks and ensures that the hydraulic system functions optimally. Following manufacturer guidelines and using the appropriate tools are key steps in achieving a reliable and secure connection.

Types of Hydraulic Hose Fittings

JIC (Joint Industry Council)

Also known as 37° flare fittings, these are widely used in hydraulic systems and are known for their reliable sealing properties.

SAE

These fittings have a 45° flare and are commonly used in automotive applications.

NPT

NPT fittings have tapered threads and are frequently used for fluid transfer in hydraulic systems.

ORFS

These fittings have an O-ring on the face to create a seal, and they are popular for high-pressure applications.

BSP

BSP fittings are commonly used in European markets and have parallel threads.

Metric

These fittings are used in metric-sized hydraulic systems and have parallel threads like BSP fittings.

Flange Fittings

Flange fittings connect hoses to a flat surface and are ideal for high-pressure applications.

Banjo Fittings

These fittings have a circular, flat end with a hole for a bolt to pass through, commonly used for tight spaces.

Quick Disconnect (QD) Couplings

These allow for easy, quick connection and disconnection of hydraulic lines.

Compression Fittings

These fittings use compression to create a seal and are commonly used in instrumentation systems.

Camlock Fittings

These are quick-connect fittings that are easy to attach and detach.

Push-to-Connect Fittings

These fittings allow for quick and easy connection without the need for tools.

Barbed Fittings

These have barbs to secure the hose in place and are often used in low-pressure applications.

Suction Hose Fittings

These are designed specifically for suction hoses, ensuring a secure connection.

Bite-Type Fittings

These fittings create a seal by biting into the hose, providing a secure connection.

Conclusion

Key Points

In conclusion, understanding the key points discussed in this guide is essential for maintaining the reliability and longevity of hydraulic hoses. We’ve covered the importance of proper fittings, the various types of fittings available, and the significance of ensuring secure connections. Additionally, we’ve explored common causes that require hydraulic hose repair service, including environmental factors, operational errors, and material/manufacturing issues. Armed with this knowledge, you can make informed decisions to optimize your hydraulic system’s performance while minimizing the risk of hose failures.

Final Advice on Hydraulic Hose Care

As a parting piece of advice, remember that proactive maintenance and regular inspections are the best strategies for preserving your hydraulic hoses. Routinely check for wear, damage, and proper fittings, and replace hoses when needed. Always adhere to manufacturer guidelines for installation, operation, and maintenance. By prioritizing hose care and taking preventative measures, you can ensure the smooth operation of your hydraulic systems and avoid costly downtime and repairs.