All About Hydraulics ~ Protect Your Hydraulic Cylinders from Extreme Heat and Cold

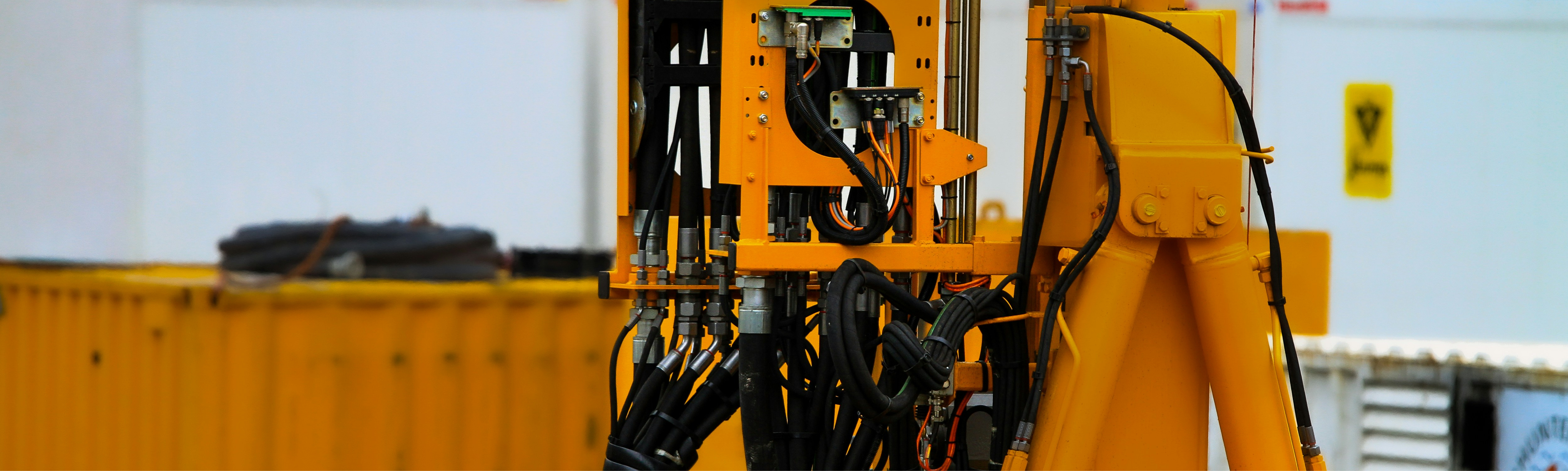

Looking to learn all about hydraulics? You’ve come to the right place! Your hydraulic systems are made to handle demanding work conditions and harsh environments. But even the most rugged, high-performing equipment can fail due to certain harsh conditions. In work environments that involve high and low temperatures, the hydraulic cylinders and the components of these robust systems are prone to damage.

Whether you operate mobile or industrial hydraulic equipment, use these tips below to help you understand all about hydraulics, the effects of high and low temperatures on your hydraulic systems, and how to protect them from damage.

Protecting Your Hydraulic Cylinders in Extreme Heat

Hydraulic systems generate heat as they operate. If the temperature reaches 180 degrees or above, that’s when the system can experience negative effects. Whether they are from mechanical or environmental sources, they can do damage to your hydraulic system.

High Temperatures and Hydraulic Fluid Viscosity

Oil tends to thin out when heat is added to the situation. Hydraulic fluid and lubricants get thin and have lower viscosity, which ends up causing wear and tear to the hydraulic system. Heat can be considered a contaminant to hydraulic cylinder fluid because of how much it can change the properties of the fluid. Lower fluid viscosity and oxidation affect how well the fluid lubricates the hydraulic cylinder components.

Always make sure to keep an eye on hydraulic fluid to keep it from becoming a contaminate, or too thin to properly function.

Changes to Hydraulic Cylinder Seals

High temperatures can result in seal failure. This is when different properties of the system adjust based on the heat that is applied and the seals can harden, crack or lose their elasticity. All of these malfunctions to the seal can cause leaks, contamination, and possible damage to other properties.

Seals that have been compromised could cause permanent damage, so it’s best to check on the machinery often to ensure the seal is still intact and not causing any harm to the rest of the components.

High Temperatures and Oxidation

Oxidation is a chemical reaction that can happen in hydraulic systems and lead to many different issues. Heat quickens the oxidation process, which leads to the oxidation producing sludge and varnish that will end up clogging lines and valves. Oxidation will result in a low-quality and inefficient hydraulic cylinder. Worst case scenario is system failure – keep in mind the higher the temperature, the faster the oxidation process goes (best not to exceed 150 degrees).

Protecting Hydraulic Cylinders in Extreme Cold

All Phase Hydraulics is based in Michigan, so we are very familiar with those cold temperatures! We also know that exposure to low temperatures is hard on your hydraulic cylinders, especially the seals and fluid.

Low Temperatures and Hydraulic Fluid Viscosity

Hydraulic fluid has a freezing point of -10 F (-23 C), but even temperatures above the freezing point can change the fluid viscosity. Quite the opposite of how heat affects hydraulic fluid, cold temperatures cause the fluid to thicken, making it more difficult for the fluid to move through your system. This can result in damage to the pumps and poor efficiency.

Using hydraulic fluid with a lower viscosity grade can help prevent hydraulic cylinder failure in those colder temperatures. Another way to maintain the fluid viscosity in colder temperatures is using an externally mounted heat source. There are many different types of heating elements you can purchase to keep the hydraulic fluid at the right temperature and viscosity.

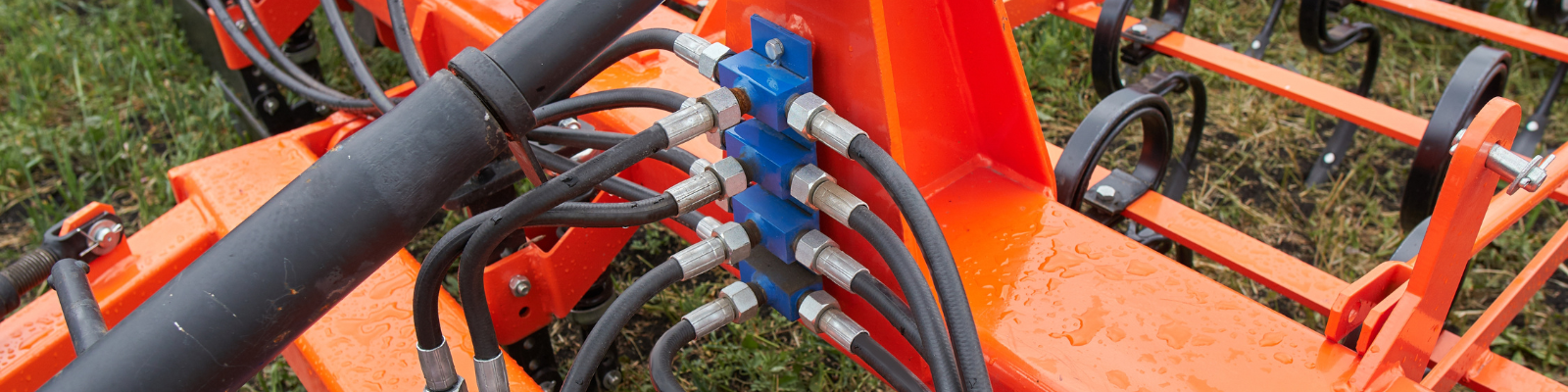

How Cold Affects Cylinder Seals and Components

Cold temperatures can lead to cylinder seals breaking or cracking, leading to the seals not having the ability to prevent leaks, so that contamination occurs in the rest of the system.

Hydraulic hoses can also suffer from cold weather. They aren’t as flexible and are more vulnerable to cracking and breaking.

Both of these issues can lead to more damage to the system and even potential failure, depending on how bad the issue gets. Always keep an eye on the system to make sure it’s functioning correctly and you are doing your best to prevent any potential damage, or any potential damage from getting worse.

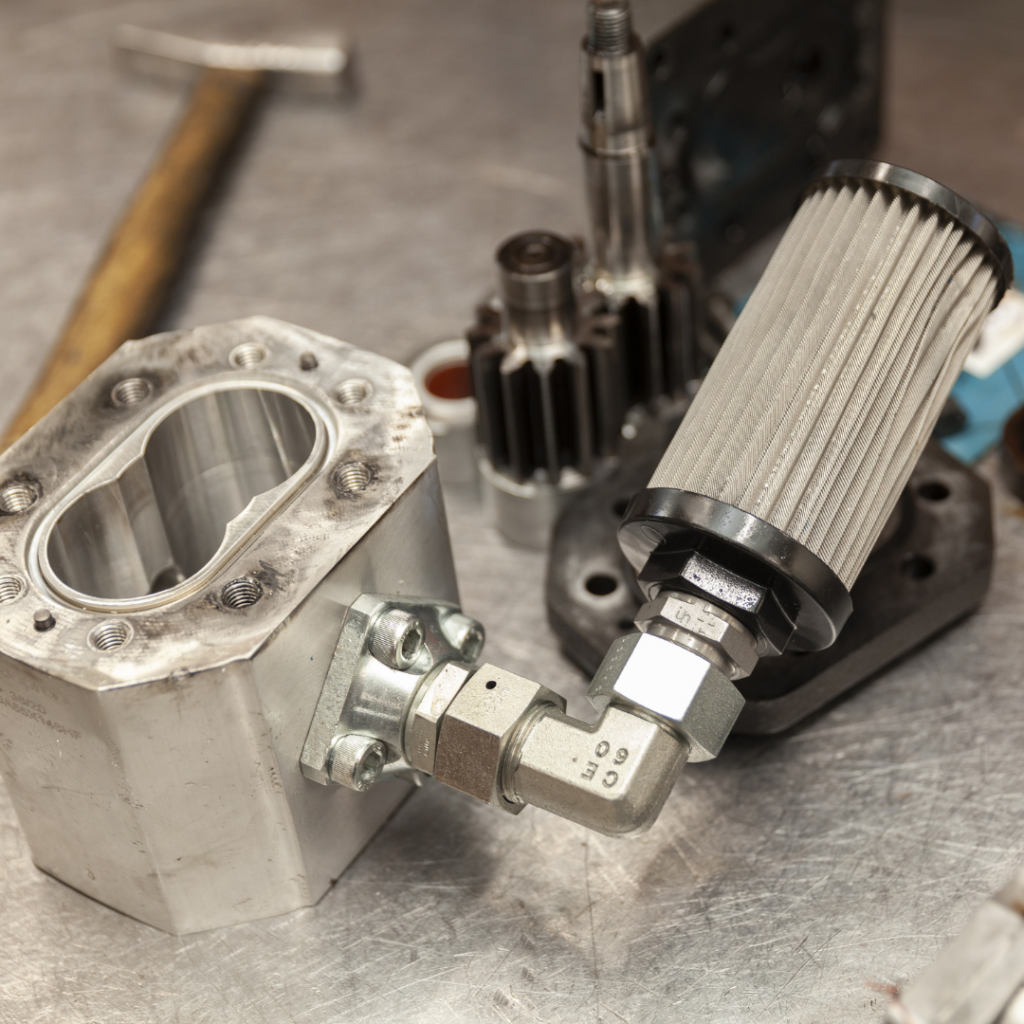

Preventative Maintenance and Using the Right Parts Make a Difference

- Use the correct fluids – only the fluid that is designed specifically for your hydraulic system

- Keep the fluid clean and keep contaminants away – change the fluid regularly

- Check for leaks often – if you find leaks? Repair them ASAP

- Don’t overload your hydraulic system – know the limit, and don’t let it go over that

- Cooling system as needed – if the machine operates in heat? you may need a cooling system to keep it from overheating

All Phase Hydraulics has the parts you need. Everything from custom cylinders to high-quality replacement parts. Our hydraulic cylinders are made in the USA and designed with you in mind to meet your specific applications and work environment. Contact us to discuss your application requirements!