How Often Should I Refinish the Chrome on my Equipment?

The longevity of chrome refinishing services on your equipment largely depends on the condition and environment in which you most frequently work. Most experts recommend re-chroming services every couple of decades in non-wear circumstances, even if you work in harsh conditions. Factors that will require hydraulic re-chroming services are commonly determined by:

- The thickness of your current chrome plating layer

- How often regular equipment maintenance and proper routine care are performed

- The quality of chrome plating materials

The chrome plating provides a clean and attractive finish intended to protect your equipment from wear, impact, and corrosion. If you notice early signs of damage or rust, you may need re-chroming services sooner rather than later.

Benefits of a Chrome Refinishing Service for your Equipment

The re-chroming process involves using an electrical current to apply a thin layer of metallic chromium to a surface. When a proper coating thickness is applied to equipment like hydraulic cylinders, pistons, and other mechanical components, it delivers durable and dependable protection against excessive wear and corrosion buildup.

Ever wonder why steel and other materials are naturally strong and can withstand heavy-duty use, yet you still need to invest in chrome refinishing services? Well, by having the chrome plated on your equipment routinely refinished, you can have an extra layer for better wear and rust resistance for improved performance as well as the following re-chroming benefits:

- Added flexibility to apply hard chrome on a range of different materials, including brass, copper, and stainless steel.

- Ability to finish those irregular surfaces and shapes that are hard to reach inside holes, tight spaces, and bores.

- Increasingly long-term protection capacity with a decreased risk of flaking or delamination during the coating’s lifespan.

- Low-temperature application causes little damage or effects on the substrate metal surface.

When you invest in quality chroming services that prevent corrosion, improve wear resistance, and increases the material’s hardness- you can expect to minimize additional operating expenses and reduce work downtime.

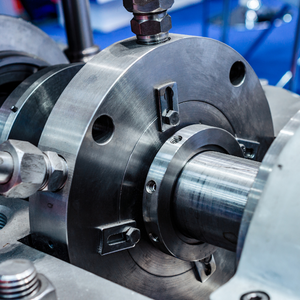

Before Rechroming Service

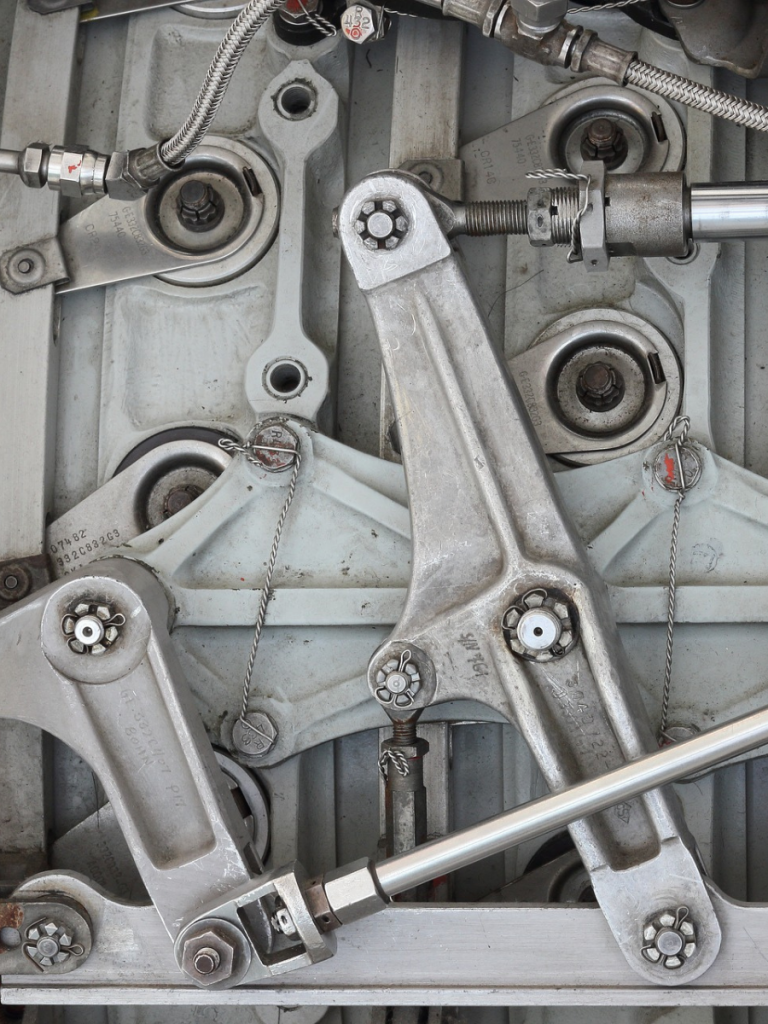

After Rechroming Service

Why Choose All Phase Hydraulics for Your Hydraulic Rechroming Services?

All Phase Hydraulics is dedicated to helping you improve your business and continue your operations. We offer custom rechroming services for your cylinders to keep your productivity high and your repair costs low. Our premium, multi-step rechroming services will get your cylinders where they need to be in order to keep you working and your business in motion. It is important to get your cylinders rechromed before it becomes a problem.

Give Us a Call Today to Learn More about our Rechroming Services!